Solidworks (Mechanical)

Solidworks (Mechanical)

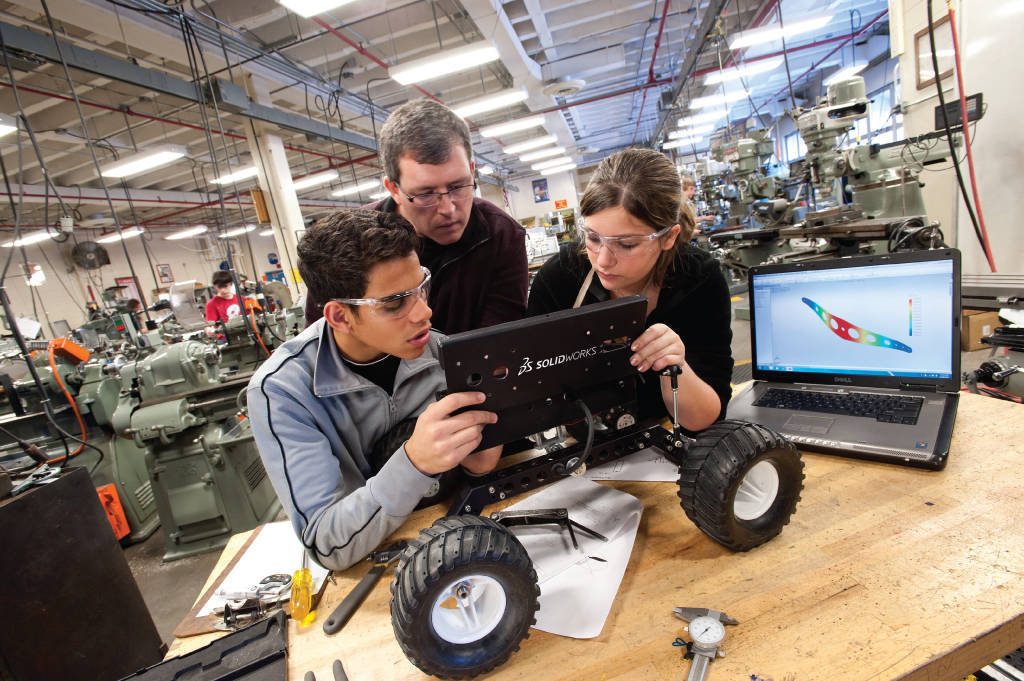

CADME is the Authorized Training centre for SolidWorks in Coimbatore for all students and professionals to focus on ideas, problem-solving techniques, and innovation-instead of memorizing complex commands. You will benefit from an experience that more closely represents real-world mechanical engineering.

SOLIDWORKS training courses can help you achieve your goals, whether you want to improve your skills, resume training, or learn how to use SOLIDWORKS tools for the first time. Through 3D modeling, virtual simulation, curriculum, and lessons, SOLIDWORKS provides a way to demonstrate your expertise in solid modeling software design concepts, as well as sustainable design, and your commitment to professional development.

CAME as a Solidworks training center in Coimbatore offers wide range of SollidWorks training programs with Solidworks Certifications.

SolidWorks Basics

Introduction, SolidWorks basics and user interface, Sketching fundamentals, Basic part modeling, Symmetry and Draft, Pattering, Revolving features, shelling and Ribs, Editing: repairs, Design changes, Configurations.

SolidWorks drawing views, Annotations, Dimensioning tools, Sheet Formats and Templates, Draft sight, E-drawings.

Bottom-up assembly, Standard mate techniques, Part configurations in assembly, Sub-assembly creation, Smart mates, Inserting sub-assembly, Analyzing techniques of assembly, Assembly properties, Static vs dynamic interference, Clearance verification, Assembly exploded view settings, Bill of materials.

CAD Professional

Introduction,SOLIDWORKS Basics and the User Interface,Introduction to Sketching, Basic Part Modeling, Symmetry and Draft,Patterning, Revolved Features,Shelling and Ribs, Editing : Repairs, Editing: Design Changes, Configurations

Advanced Mate Techniques, Top-Down Assembly Modeling, Assembly Features, Smart Fasteners and Smart Components, Assembly Editing, Using Configurations with Assemblies, Layout Based Assembly Design, Large Assemblies

Drawing Sheets And Views, Dimension , Annotations, Assembly Drawing Views, Sheet Formats and Templates, Bill of Materials and Tables, Drawing References and Comparison

CAD Expert

Introduction,SOLIDWORKS Basics and the User Interface,Introduction to Sketching, Basic Part Modeling, Symmetry and Draft,Patterning, Revolved Features,Shelling and Ribs, Editing : Repairs, Editing: Design Changes, Configurations

Advanced Mate Techniques, Top-Down Assembly Modeling, Assembly Features, Smart Fasteners and Smart Components, Assembly Editing, Using Configurations with Assemblies, Layout Based Assembly Design, Large Assemblies

Drawing Sheets And Views, Dimension, Annotations, Assembly Drawing Views, Sheet Formats and Templates, Bill of Materials and Tables, Drawing References and Comparison

Multi-body Design Techniques, Saving Solid Bodies, Sketching with Splines, Introduction to Sweeping, Working with Curves, Advanced Sweeping, Boundary Feature and Lofting.

Understanding Surfaces, Introduction to Surfacing, Solid-Surface Hybrid Modeling, Repairing and Editing Imported Geometry, Advanced Surface Modeling, Blends and Patches.

Introduction, Fundamentals of Routing, Piping Route, Piping Fittings, Tubing Routes, Piping and Tubing Changes, Creating Routing Components.

Sheet Metal Flange Method, Sheet Metal Convert Method, Multi-body Sheet Metal Parts, Sheet Metal Forming Tools, Additional Sheet Metal Features and Techniques.

Weldments, Weldments Drawings.

CAE Professional

Introduction,SOLIDWORKS Basics and the User Interface,Introduction to Sketching, Basic Part Modeling, Symmetry and Draft,Patterning, Revolved Features,Shelling and Ribs, Editing : Repairs, Editing: Design Changes, Configurations

Advanced Mate Techniques, Top-Down Assembly Modeling,Assembly Features,Smart Fasteners and Smart Components,Assembly Editing,Using Configurations with Assemblies, Layout Based Assembly Design, Large Assemblies

Drawing Sheets And Views, Dimension , Annotations , Assembly Drawing Views , Sheet Formats and Templates , Bill of Materials and Tables , Drawing References and Comparison

Multi-body Design Techniques, Saving Solid Bodies, Sketching with Splines, Introduction to Sweeping, Working with Curves, Advanced Sweeping, Boundary Feature and Lofting.

The Analysis Process, Mesh Controls, Stress Concentrations and Boundary Conditions, Assembly Analysis with Contacts, Symmetrical and Free Self- Equilibrated Assemblies, Assembly Analysis with Connectors and Mesh Refinement, Compatible/incompatible Meshes, Analysis of Thin Components, Mixed Meshing Shells and Solids, Mixed Meshing Solids, Beams and Shells.

Frequency Analysis of Parts, Frequency Analysis of Assemblies, Buckling Analysis, Thermal Analysis, Thermal Analysis with Radiation, Fatigue Analysis, Drop Test Analysis.

Introduction to Motion Simulation and Forces, Building a motion model and post processing. Introduction to contacts, springs and dampers. Advanced contact. Curve to curve contact. Motion optimization. Flexible joints. Redundancies, Export to FEA, Event based simulation.

CAE Expert

Introduction,SOLIDWORKS Basics and the User Interface,Introduction to Sketching, Basic Part Modeling, Symmetry and Draft,Patterning, Revolved Features,Shelling and Ribs, Editing : Repairs, Editing: Design Changes, Configurations

Advanced Mate Techniques, Top-Down Assembly Modeling,Assembly Features,Smart Fasteners and Smart Components,Assembly Editing,Using Configurations with Assemblies, Layout Based Assembly Design, Large Assemblies

Drawing Sheets And Views, Dimension , Annotations , Assembly Drawing Views , Sheet Formats and Templates , Bill of Materials and Tables , Drawing References and Comparison

Multi-body Design Techniques, Saving Solid Bodies, Sketching with Splines, Introduction to Sweeping, Working with Curves, Advanced Sweeping, Boundary Feature and Lofting.

The Analysis Process, Mesh Controls, Stress Concentrations and Boundary Conditions, Assembly Analysis with Contacts, Symmetrical and Free Self- Equilibrated Assemblies, Assembly Analysis with Connectors and Mesh Refinement, Compatible/incompatible Meshes, Analysis of Thin Components, Mixed Meshing Shells and Solids, Mixed Meshing Solids, Beams and Shells.

Frequency Analysis of Parts, Frequency Analysis of Assemblies, Buckling Analysis, Thermal Analysis, Thermal Analysis with Radiation, Fatigue Analysis, Drop Test Analysis.

Introduction to Motion Simulation and Forces, Building a motion model and post processing. Introduction to contacts, springs and dampers. Advanced contact. Curve to curve contact. Motion optimization. Flexible joints. Redundancies, Export to FEA, Event based simulation.

Introduction to Nonlinear structural analysis. Geometric nonlinear analysis. Material Models and constitutive relations. Numerical procedure for nonlinear FEA, Contact Analysis, Large Displacement Analysis, Nonlinear static buckling analysis. Plastic deformation. Hardening rules. Nonlinear contact analysis.

Vibration of a Pipe, Transient shock analysis according to MILS-STD- 81OG, Harmonic Analysis of a Bracket, Response spectrum analysis. Nonlinear Dynamic Analysis of an Electronic Enclosure.

CFD Expert

Introduction,SOLIDWORKS Basics and the User Interface,Introduction to Sketching, Basic Part Modeling, Symmetry and Draft,Patterning, Revolved Features,Shelling and Ribs, Editing : Repairs, Editing: Design Changes, Configurations

Advanced Mate Techniques, Top-Down Assembly Modeling,Assembly Features,Smart Fasteners and Smart Components,Assembly Editing,Using Configurations with Assemblies, Layout Based Assembly Design, Large Assemblies

Drawing Sheets And Views, Dimension , Annotations , Assembly Drawing Views , Sheet Formats and Templates , Bill of Materials and Tables , Drawing References and Comparison

Multi-body Design Techniques, Saving Solid Bodies, Sketching with Splines, Introduction to Sweeping, Working with Curves, Advanced Sweeping, Boundary Feature and Lofting.

Creating a SOLIDWORKS Flow Simulation Project, Meshing, Thermal Analysis, and Conjugate heat transfer. Porous media. Rotating Reference frames. Parametric study. Particle Trajectory.

Diploma in CAD/CAE

Introduction,SOLIDWORKS Basics and the User Interface,Introduction to Sketching, Basic Part Modeling, Symmetry and Draft,Patterning, Revolved Features,Shelling and Ribs, Editing : Repairs, Editing: Design Changes, Configurations

Advanced Mate Techniques, Top-Down Assembly Modeling,Assembly Features,Smart Fasteners and Smart Components,Assembly Editing,Using Configurations with Assemblies, Layout Based Assembly Design, Large Assemblies

Drawing Sheets And Views, Dimension , Annotations , Assembly Drawing Views , Sheet Formats and Templates , Bill of Materials and Tables , Drawing References and Comparison

Multi-body Design Techniques, Saving Solid Bodies, Sketching with Splines, Introduction to Sweeping, Working with Curves, Advanced Sweeping, Boundary Feature and Lofting.

Understanding Surfaces, Introduction to Surfacing, Solid-Surface Hybrid Modeling, Repairing and Editing Imported Geometry, Advanced Surface Modeling, Blends and Patches.

Introduction, Fundamentals of Routing, Piping Route, Piping Fittings, Tubing Routes, Piping and Tubing Changes, Creating Routing Components.

Sheet Metal Flange Method, Sheet Metal Convert Method, Multi-body Sheet Metal Parts, Sheet Metal Forming Tools, Additional Sheet Metal Features and Techniques.

The Analysis Process, Mesh Controls, Stress Concentrations and Boundary Conditions, Assembly Analysis with Contacts,Symmetrical and Free Self- Equilibrated Assemblies, Assembly Analysis with Connectors and Mesh Refinement, Compatible / Incompatible Meshes, Analysis of Thin Components, Mixed Meshing Shells and Solids, Mixed Meshing Solids, Beams and Shells.

Introduction to Nonlinear structural analysis. Geometric nonlinear analysis. Material Models and constitutive relations. Numerical procedure for nonlinear FEA, Contact Analysis, Large Displacement Analysis, Nonlinear static buckling analysis. Plastic deformation. Hardening rules. Nonlinear contact analysis.

Frequency Analysis of Parts, Frequency Analysis of Assemblies, Buckling Analysis, Thermal Analysis, Thermal Analysis with Radiation, Fatigue Analysis, Drop Test Analysis.

Introduction to Motion Simulation and Forces, Building a motion model and post processing. Introduction to contacts, springs and dampers. Advanced contact. Curve to curve contact. Motion optimization. Flexible joints. Redundancies, Export to FEA, Event based simulation.

Introduction to Nonlinear structural analysis. Geometric nonlinear analysis. Material Models and constitutive relations. Numerical procedure for nonlinear FEA, Contact Analysis, Large Displacement Analysis, Nonlinear static buckling analysis. Plastic deformation. Hardening rules. Nonlinear contact analysis.

Vibration of a Pipe, Transient shock analysis according to MILS-STD- 81OG, Harmonic Analysis of a Bracket, Response spectrum analysis. Nonlinear Dynamic Analysis of an Electronic Enclosu

Mold Design

Introduction, SOLIDWORKS Basics and the User Interface, Introduction to Sketching, Basic Part Modeling, Symmetry and Draft, Patterning, Revolved Features, Shelling and Ribs, Editing: Repairs, Editing: Design Changes, Configurations.

Advanced Mate Techniques, Top-Down Assembly Modeling,Assembly Features,Smart Fasteners and Smart Components,Assembly Editing,Using Configurations with Assemblies, Layout Based Assembly Design, Large Assemblies

Drawing Sheets And Views, Dimension , Annotations , Assembly Drawing Views , Sheet Formats and Templates , Bill of Materials and Tables , Drawing References and Comparison

Surface Concepts and Imported Geometry, Core and Cavity, Side Cores and EDM Design, Advanced Parting Lines, Shut-Off Surfaces and Cores, Using Surfaces for Model Prep and Interlocks, Using Surfaces for Mold Design Features, Completing the Mold Base.

Basic Flow Analysis, Detecting Air Traps, Detecting Short Shots, The Model Manager, Injection Locations and Sink Marks, Multiple Cavity Molds, Runner-Balancing, Gate Freeze, Optimizing Cooling.

So What You Think?

For futher details or if you have any queries, contact us. We,

will provide you the respective details.