Geometrical Dimensioning & Tolerances (GD&T)

Geometrical Dimensioning & Tolerances (GD&T)

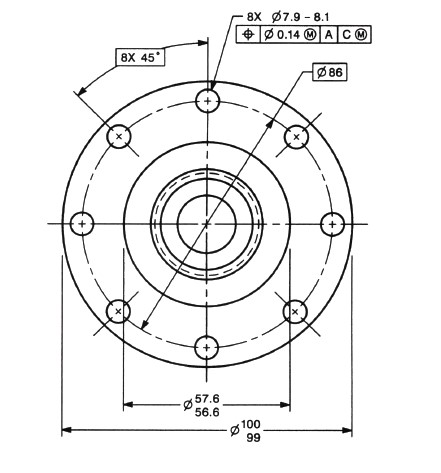

Geometric dimensioning and tolerancing is a language used on drawings to accurately describe a part how to be manufacture and inspected. This Training program may be based on the ASME standards (ASME Y14.5M-1994, Y14.5-2009) or on ISO standards (ISO 1101, ISO 5459, etc.). The course is basically designed for anyone who is involved in designs, drafts, engineers, manufactures, and inspects the parts and assemblies.

CADME offers GD&T Training programs as a value-added topic for Mechanical industry most wanted knowledges. We conduct these programs with Instructors with vast experience in this field. CADME in one of the Best GD&T training centers in Coimbatore.

Benefits of GD&T:

- Interpretation of Detail Drawings by Design, Manufacturing and Inspection Teams in the same manner

- Reduces Tolerances and ensure meeting of Fit, Form and Functional requirements

- Drastically improves quality, reduces cost and eliminates Re-work

Prerequisites:

- Have a working understanding of technical drawings.

GD&T Fundamental Course Outline

GD&T Basics Course

A thorough and rigorous treatment of the system of Geometric Dimensioning and Tolerancing concepts, rules, legal implications, tools and techniques are presented in detail from design, inspection, and concurrent engineering points of view. (ASME or ISO GD&T)

GD&T Application Course

Training Covers the more advanced topics, application issues, pros and cons of alternate strategies, effects on downstream processes and the supply chain, and includes many application-based exercises. (ASME or ISO GD&T)

GD&T Advanced Course Outline

GD&T Advanced Course

Advanced topics, problems and challenges in Dimensioning and Tolerancing, advanced feature types and tolerancing techniques, challenges in metrology, mathematical concepts, effects on Tolerance Stack-ups, mating part applications, and optional strategies.(ASME)

Tolerance Analysis Course

Understand how to calculate and manage variation and its implications on product performance. (ASME or ISO GD&T)

So What You Think?

For futher details or if you have any queries, contact us. We,

will provide you the respective details.